Hyde Information | Added a batch of new magnesium alloy production equipment

Published Time:

2024-01-06

To improve production efficiency and meet customer supply needs faster and more comprehensively, Guangzhou Hyde Auto Parts Co., Ltd. has purchased a batch of new magnesium alloy production equipment.

Haide Auto Parts introduces a batch of magnesium alloy production equipment

In order to improve production efficiency and meet customer supply needs faster and more comprehensively, Guangzhou Haide Auto Parts Co., Ltd. has newly purchased magnesium alloy production equipment: Yizumi HII series 650T die-casting machines and 3 CNC machining centers, and 5 sets of professional magnesium alloy polishing equipment. The new equipment adopts the most advanced technology and is characterized by high efficiency, intelligence, and reliability. It can quickly and accurately complete complex processing tasks, improving production efficiency and work efficiency, effectively shortening the production cycle, and significantly improving product quality.

New CNC machining center equipment

New die-casting equipment

New post-processing polishing equipment

The current domestic development status of the magnesium alloy industry

As the lightest metallic structural material, magnesium alloy has enormous application potential in the fields of aerospace, automotive, high-speed rail, and communications, becoming one of the most promising metallic structural materials. China is a major magnesium resource country, possessing abundant magnesium ore resources and magnesium salt lake resources. Since 2003, China has been the world's largest producer and exporter of primary magnesium for 18 consecutive years. Vigorously promoting the industrial application of magnesium alloys is not only an important measure for lightweight structural materials and environmental protection, but also an important measure to make full use of China's abundant resources and alleviate dependence on imports of iron and aluminum ore resources, which is of extremely important strategic significance, especially under the complex and changing international situation.

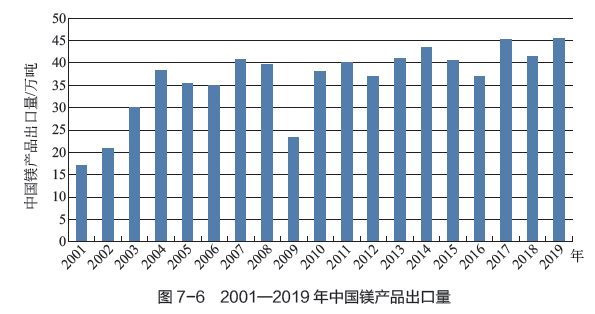

According to statistics from the China Nonferrous Metals Industry Association, in 2019, China's primary magnesium production reached 969,000 tons, a year-on-year increase of 12.2%. Currently, about 45% of the world's primary magnesium is used to produce magnesium alloys, 70% for the automotive industry, 20% for 3C electronic products, and 10% for military applications. As shown in Figure 7-6, in 2019, China exported 451,600 tons of primary magnesium and magnesium products, accounting for 53% of the global total output. Deep-processed magnesium alloy products are mainly produced by die casting, but there are certain limitations, which restrict the large-scale expansion of magnesium alloy applications. Deformable magnesium alloy products need further breakthroughs in processing technology and application technology.

Market demand and application prospects of magnesium alloys

1. Application of magnesium alloys in the automotive field

In recent ten years, China's automobile ownership has steadily increased, and oil consumption accounts for 59% of the total oil consumption. China's automobile lightweight effect is relatively low, and the average fuel consumption per 100 kilometers is much higher than that of foreign developed countries, putting great pressure on the environment. Compared with steel and aluminum, the lightweight effect of using magnesium alloy components is more significant. For every 1kg of magnesium used, 30kg of exhaust emissions can be reduced during the car's lifespan. Currently, North American automakers use 1.5 to 3.5kg of magnesium per vehicle, and some models have exceeded 20kg. According to China's automobile lightweight roadmap, the amount of magnesium alloy used per vehicle should reach 15kg, 25kg, and 45kg by 2020, 2025, and 2030, respectively. Based on the production of 35 million vehicles in 2025 and a consumption of 25kg of magnesium alloy per vehicle, the demand will be 875,000 tons. Based on a per-vehicle usage of 45kg in 2030, 1.72 million tons will be needed. In 2019, China produced 1.3 million pure electric vehicles and 25 million small passenger vehicles. If only the coverings of each vehicle were changed to 65kg magnesium alloy plates, 2.03 million tons would be needed. FAW Car Co., Ltd., SAIC Volkswagen, and Changan Automobile have begun to use magnesium alloys in large quantities. Looking to the future, the amount of magnesium alloy used in automobiles is expected to experience explosive growth.

Foreign countries attach great importance to the application of magnesium alloys in automobiles and have long launched medium- and long-term plans to promote the application of magnesium alloys in automobiles. In order to accelerate the application of magnesium alloys in automobiles, General Motors has conducted more than 10 years of technical cooperation with Chongqing University, Shanghai Jiao Tong University, and other institutions. China also attaches great importance to the application of magnesium alloys in automobiles. Since 2000, the Ministry of Science and Technology, the National Development and Reform Commission, the Ministry of Industry and Information Technology, and other departments have arranged a number of national and provincial projects such as "Research and development and industrialization of common key technologies for the production and application of magnesium alloy components for vehicles" and "Research and application of high-performance magnesium alloys", making important progress in new high-strength magnesium alloy materials, magnesium alloy die-casting technology, magnesium alloy rolling and extrusion processing technology, and magnesium alloy connection technology, laying a solid foundation for the further application of magnesium alloy materials. More than 50 magnesium alloy automotive parts have been developed, such as steering wheel cores, electrical brackets, rear window frames, door inner frames, auxiliary rotating brackets, etc., and have been installed in more than 50 million vehicles, achieving good economic and social benefits.

Therefore, in the field of transportation vehicles such as automobiles and motorcycles, magnesium alloys fully demonstrate their advantages of being lightweight and having excellent vibration damping performance. They have been used on a large scale in power transmission systems represented by engines and transmissions, driving and steering systems represented by sub-frames, wheel hubs, suspensions, and steering gears, and body and interior systems represented by car bodies, doors, front and rear compartments, instrument panel brackets, seat frames, and central control brackets. According to China's latest automobile lightweight roadmap, the future application of magnesium alloys in automobiles will exceed 100kg/vehicle.

2. Application of magnesium alloys in rail transit equipment

China's rail transit has developed rapidly. Due to energy shortages and higher requirements for energy saving, emission reduction, safety, and comfort, lightweight rail transit equipment has become an important issue in the development of rail transit. Many newly built rail transit train equipment have begun to use lightweight materials such as aluminum alloys on a large scale, producing huge economic and social benefits. Due to its higher specific strength and specific stiffness, better vibration damping and noise reduction effects, and better electromagnetic shielding effects, magnesium alloys have been initially applied on a large scale in some rail transit interior parts and connecting parts.

Newly built and soon-to-be-updated rail transit equipment are potential application targets for magnesium alloy materials and products. The annual output of rail transit trains represented by Changchun Railway Vehicle Factory and Tangshan Railway Vehicle Factory has been around 3,000 in recent years, and the output value will exceed 120 billion yuan. Magnesium products from magnesium alloy processing enterprises such as Shanxi Yinguanghua Sheng Magnesium Industry have been used in more than 100 subway lines and more than 400 high-speed rail lines, reducing the weight of the entire vehicle body, significantly improving the train's power, and reducing energy consumption. With the rapid development of rail transit and the progress of magnesium alloy material preparation and processing technology, magnesium alloy materials and products with excellent performance will surely be more widely used in rail transit equipment.

3. Application of magnesium alloys in electric bicycles

The national ownership of electric bicycles has exceeded 230 million units, with an annual output consistently above 20 million units. However, over 80% of current electric bicycles are non-compliant products (in terms of weight and maximum speed). According to current national standards, the maximum speed of electric bicycles should not exceed 20km/h, and the total vehicle weight should not exceed 40kg. For electric bicycles with added batteries, lightweighting is a very important choice. After a significant reduction in overall vehicle weight, the riding distance after a single charge will be further extended. Magnesium alloy has good vibration damping and high comfort; it has good heat dissipation, which can lower brake system temperature and extend brake hub lifespan. Lighter magnesium alloy wheels are beneficial for improving acceleration and braking performance.

Currently, many enterprises in Tianjin, Hebei, Zhejiang, Shanxi, Shandong, and other regions are producing magnesium alloy bicycle and electric bicycle components. In addition to magnesium alloy body parts such as frames, kickstands, fenders, and struts, the application of magnesium alloy wheels has further increased the amount of magnesium alloy used per bicycle. If 50% of electric bicycles each use 5kg of magnesium alloy, it will add an 80,000-ton magnesium alloy market annually.

4. Application of Magnesium Alloys in LED Lighting Fixtures

LED is recognized as the most promising fourth-generation green light source. Although the thermal conductivity of magnesium alloys is inferior to that of aluminum, the heat dissipation effect of magnesium alloy components is superior to that of aluminum alloys, which provides an excellent opportunity for the promotion and application of magnesium alloys in the LED industry where heat dissipation requirements are high.

The magnesium alloy components applied in the LED lighting field mainly include street light housings and lamp frames, lamp tube profiles, downlight housings, bulb lamp housings, tunnel light housings, and LED heat dissipation modules. This includes magnesium alloy die-cast parts and profiles, with surface treatments using fluorocarbon spraying, plastic spraying, and anodic oxidation. According to preliminary estimates, the application of magnesium alloy in the LED industry will reach 20,000 tons in 2020.

5. Application of Magnesium Alloys in 3C Products

Magnesium alloys have been widely used in laptop casings, with mainstream brands like HP, Dell, and Lenovo currently using them extensively, and the application volume is on an upward trend. Using magnesium alloy extruded plates for CNC machining of 3C product casings can achieve better mechanical properties and appearance quality. Therefore, almost all Microsoft tablet computer casings use magnesium alloy extruded plates, with a procurement volume of around 15,000 tons in 2017 alone. 3C products using magnesium alloy also include projectors, digital cameras, network communication equipment, audio-visual equipment, and more.

6. Application of Magnesium Alloys in Aerospace and Military Key Equipment

Magnesium alloy materials, with advantages such as lightweight, high specific strength, high specific stiffness, damping vibration reduction, electromagnetic shielding, excellent casting and machining properties, and easy recyclability, are playing an increasingly crucial role in the lightweighting and weight reduction of major national projects like large aircraft, manned spaceflight, and lunar exploration, as well as in military fields. They are gaining increasing attention and their application scope is gradually expanding.

In aircraft structures, besides internal support frames, wide magnesium alloy sheets are most suitable for use as skins, floors, and cabin panels. Test results show that the economic benefits of reducing aircraft weight by 1 pound are $300 for commercial aircraft, $3,000 for fighter jets, and $30,000 for spacecraft. The comprehensive weight reduction effect is 25% to 35% higher than that of aluminum alloys. European Airbus developed magnesium alloy plates as early as the 20th century, achieving a weight reduction of tens of tons compared to using aluminum alloys. China's Xi'an Aircraft Industry Group (XAC) and Chengdu Aircraft Industry Group (CAC) have long used magnesium alloy forgings, castings, and sheets in aircraft bodies. High-performance magnesium alloys have enormous application potential in aerospace and key military equipment fields. With the development of high-performance magnesium alloys, their application potential in aircraft engine accessory casings, intake casings, thrust reverser cascades, helicopter transmission system casings, missile bodies, missile wings, satellite bodies, fighter cockpit frames, lunar rover robotic arms, armored vehicle engine components, wheels, frames, satellite components, tank parts, and other fields will gradually be unleashed.

7. Application of Magnesium Alloys in Oil and Gas Drilling and Production

Magnesium alloys are prone to corrosion due to their low electrode potential. By adding Cu or Ni elements to magnesium alloys, their degradation rate can be further increased, while simultaneously achieving high strength and high degradation rate. This has important application value for the development of multi-stage segmented fracturing technology and has huge application prospects in the oil and gas exploration and production field. It is estimated that future demand will exceed 2 billion yuan per year.

8. Application of Magnesium Alloys in Energy Storage Materials

Magnesium-based energy storage materials primarily include magnesium-based hydrogen storage materials and magnesium batteries. Magnesium and its alloys can form Mg-H compounds with hydrogen, such as Mg2Ni, Mg2Cu, Mg(BH4)2, and other magnesium-based hydrogen storage materials, with stable hydrogen storage mass fractions ranging from 2% to 15%. They also exhibit good hydrogen absorption and desorption kinetics, with some systems operating very close to the working temperature of proton exchange membranes in fuel cells (around 80°C), laying the foundation for future large-scale applications. The application of magnesium batteries will be a disruptive revolution in the battery industry, with a market capacity exceeding one trillion US dollars.

9. Application of Magnesium Alloys in Other Fields

The usage of magnesium alloys in textile machinery has steadily increased, with cumulative installations exceeding 10 million sets, and textile breakage rates decreasing by over 60%, fully leveraging the vibration damping advantages of magnesium alloys. For example, magnesium alloy components for Jacquard bases in textile machinery have achieved large-scale application, with products exported to countries such as France, Japan, and South Korea, achieving good social and economic benefits.

In the field of intelligent equipment, magnesium alloys, due to their lightweight and vibration damping advantages, can significantly improve equipment precision and extend service life, demonstrating enormous market potential. Due to their relatively active chemical properties, magnesium alloys will be further widely used in sacrificial anodes, battery anodes, and other applications.

Company Profile

Guangzhou Haide Auto Parts Co., Ltd. was established on January 20, 2009, and is located at No. 231 Juhuashi Avenue, Huashan Town, Huadu District, Guangzhou City, Guangdong Province. In 2016, its subsidiary, Guangzhou Hongde Industrial Co., Ltd., was established, and in 2021, Guangzhou Haide Auto Parts Co., Ltd. Shunde Branch was established.

Our company mainly specializes in aluminum, zinc, and magnesium alloy die-casting, precision mechanical processing, surface coating treatment, and overall product assembly solutions for industries such as automotive parts, LED stage lighting, electromechanical, and communication equipment.

The company has obtained TUV Rheinland ISO9001 quality management system certification, IATF16949 automotive quality management system certification, ISO14001/45001 occupational health system certification, intellectual property standardization certification, provincial "specialized, refined, distinctive, and innovative" enterprise, and high-tech enterprise certification.

And with advanced production equipment and an excellent management team, we provide customers with a complete set of professional process solutions for die casting, precision machining, surface coating, and product assembly.

20+ years focused on the die-casting industry

Guangzhou Haide Auto Parts Co., Ltd.

Address: No. 231 Juhuashi Avenue, Huashan Town, Huadu District, Guangzhou City

Phone: 020-86788986

Keywords:

Related News

Address: No. 231, Juhuashi Avenue, Chengxi Village, Huashan Town, Huadu District, Guangzhou City

Tel: 020-86788986/ +86 13432077858 Ms. Liu

Cooperation Hotline: +86 13925100803 Mr Zhang

Email: hddf@vip.163.com / hdxz@gzhead.com

Follow us